Introduction

Singapore has long been recognized as a global hub for manufacturing, driven by its strategic location, advanced infrastructure, and a skilled workforce. Within this vibrant sector, high-quality metal products have become increasingly pivotal to the success and sustainability of manufacturing operations. As industries evolve and demands shift, the importance of investing in quality metal products cannot be overstated. This blog will delve into the myriad advantages that high-quality metal products offer to Singapore's manufacturing sector, highlighting how they contribute to durability, performance, safety, sustainability, and overall competitiveness.If you need more information, check this website. https://skind.com.sg/

The Role of Metal in Manufacturing

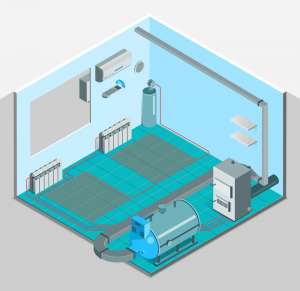

Before exploring the advantages of high-quality metal products, it is essential to understand their role in the manufacturing landscape. Metals such as steel, aluminum, and titanium are foundational materials used in a wide array of applications, from automotive parts and construction components to electronics and consumer goods. The properties of metals—such as strength, malleability, and conductivity—make them indispensable in manufacturing processes.

In Singapore, where industries range from precision engineering and electronics to aerospace and biotechnology, the demand for high-quality metal products is particularly pronounced. As manufacturers seek to innovate and improve efficiency, the materials they choose can significantly impact their operations.

Durability and Longevity

One of the foremost advantages of high-quality metal products is their exceptional durability. Metals that are manufactured to high standards are less prone to corrosion, wear, and damage. For example, stainless steel products are widely used in manufacturing due to their resistance to rust and staining, which ensures that they maintain their integrity even in challenging environments.

Benefits of Durability:

- Reduced Replacement Costs: High-quality metal products last longer, resulting in fewer replacements and lower capital expenditures over time.

- Lower Maintenance Needs: Durable products require less frequent maintenance, allowing manufacturers to allocate resources more effectively and reduce downtime.

- Reliability in Operations: Consistent performance over time builds trust in the materials, allowing manufacturers to plan and execute operations with greater confidence.

2. Enhanced Performance

In a competitive manufacturing environment, performance is crucial. High-quality metal products can significantly enhance the operational efficiency of machinery and equipment. Precision engineering and high manufacturing standards ensure that metal components fit together seamlessly, minimizing friction and energy loss during operation.

Impact on Performance:

- Increased Efficiency: Equipment that operates smoothly and efficiently can produce more output with less energy, which is vital for maintaining profitability.

- Better Product Quality: High-performance materials contribute to the quality of end products, which is essential in sectors like electronics and aerospace where precision is non-negotiable.

- Improved Innovation: With better-performing materials, manufacturers can explore innovative designs and functionalities, setting themselves apart in the market.

3. Increased Safety

Safety is paramount in any manufacturing operation, and high-quality metal products contribute significantly to workplace safety. Components that are poorly manufactured can lead to equipment failure, accidents, and costly liabilities. In contrast, high-quality materials adhere to stringent safety standards, mitigating these risks.

Safety Advantages:

- Fewer Failures and Accidents: Durable and reliable metal products reduce the likelihood of breakdowns that could endanger workers.

- Compliance with Regulations: High-quality products often meet or exceed industry safety standards, helping manufacturers avoid legal complications and penalties.

- Enhanced Worker Confidence: A safer work environment fosters confidence among employees, leading to higher morale and productivity.

4. Sustainability and Environmental Impact

In today's manufacturing landscape, sustainability is a critical concern. High-quality metal products align well with environmentally responsible practices. Many metals can be recycled without losing their properties, contributing to a circular economy.

Sustainability Benefits:

- Recyclability: Metals like aluminum and steel are highly recyclable, reducing the demand for raw materials and minimizing environmental impact.

- Energy Efficiency: High-quality metal products often require less energy to manufacture and maintain, contributing to lower carbon emissions.

- Sustainable Practices: Manufacturers can leverage high-quality materials to promote their commitment to sustainability, enhancing their brand reputation among eco-conscious consumers.

5. Customization and Innovation

The flexibility offered by high-quality metal manufacturing allows for extensive customization. Manufacturers can collaborate with suppliers to develop tailored solutions that meet specific project requirements, enhancing innovation.

Customization Advantages:

- Meeting Unique Needs: Custom metal products can be designed to fit unique operational demands, ensuring that manufacturers have exactly what they need to succeed.

- Fostering Innovation: With the ability to design specialized components, manufacturers can develop new products or enhance existing ones, driving competitive advantage.

- Adapting to Market Changes: The agility provided by customization allows manufacturers to respond quickly to changing market demands and trends.

6. Cost-Effectiveness in the Long Run

While high-quality metal products may have a higher upfront cost, their long-term benefits make them a cost-effective investment. The durability, efficiency, and performance enhancements they provide often result in substantial savings over time.

Long-Term Cost Benefits:

- Lower Operational Costs: Reduced maintenance and replacement needs contribute to significant savings, improving overall profitability.

- Improved Productivity: Efficient operations lead to higher output, which can offset initial investments in quality materials.

- Value Creation: Investing in high-quality metal products can create value for manufacturers by enhancing their brand reputation and market position.

7. Global Competitiveness

In an increasingly globalized market, the quality of products can set companies apart from their competitors. High-quality metal products can enhance a manufacturer's reputation and credibility, making it easier to enter new markets and attract international clients.

Competitiveness Advantages:

- Reputation for Quality: Companies known for using high-quality materials are more likely to gain trust and loyalty from customers.

- Attracting International Clients: Quality products can open doors to international markets, allowing manufacturers to expand their reach and increase revenue.

- Standards Compliance: High-quality metal products often meet global standards, facilitating international trade and partnerships.

8. The Role of Technology in Metal Manufacturing

Advancements in technology have revolutionized metal manufacturing, leading to improved quality and efficiency. Automation, precision machining, and innovative materials science contribute to the production of high-quality metal products.

Technological Impact:

- Precision Engineering: Modern manufacturing techniques allow for tighter tolerances and better surface finishes, leading to higher-quality components.

- Automation and Efficiency: Automated processes increase production speed and consistency, minimizing human error and enhancing overall product quality.

- Research and Development: Ongoing R&D in material sciences leads to the creation of advanced alloys and composites, further elevating the quality of metal products.

9. Case Studies in Singapore's Manufacturing Sector

To illustrate the benefits of high-quality metal products, let's look at some case studies from Singapore's manufacturing sector:

-

Electronics Industry: A leading electronics manufacturer in Singapore adopted high-quality aluminum enclosures for their devices. The enhanced durability of the enclosures not only improved the product's lifespan but also reduced production costs due to fewer returns and replacements.

-

Aerospace Sector: A Singapore-based aerospace company utilized high-strength titanium components in their aircraft. The lightweight yet durable properties of titanium allowed for significant fuel savings, aligning with the industry's push for sustainability while enhancing aircraft performance.

-

Construction Industry: A construction firm specializing in high-rise buildings incorporated high-quality steel frameworks. The structural integrity and durability of the steel allowed for faster construction timelines and reduced the risk of structural failures, showcasing the importance of quality in safety-critical applications.

Conclusion

The advantages of high-quality metal products in Singapore's manufacturing sector are profound and far-reaching. From durability and enhanced performance to safety and sustainability, the benefits are clear. As manufacturers navigate the complexities of a competitive global market, investing in high-quality metal products will be essential for driving innovation, improving efficiency, and ensuring long-term success.